June 2024

Catalunya Hydrogen Week will be held from June 10th to 14th, 2024 at Port of Tarragona (Moll de Costa Tinglado 1), supported by SIEBC as a sponsor. This event gathers to promote the transition towards the use of green hydrogen, reflecting a step forward for a sustainable energy future. It offers a space for experts, scientists, entrepreneurs, and companies to engage in discussion about green economy and its future challenges.

The initiative is primarily organized by: Vall de I´Hydrogen de Catalunya, Port de Tarragona, H2CAT network, ACCIÓ – Generalitat de Catalunya, ICIQ (Catalan Institute of Chemical Research), Universitat Rovira i Virgili and Eurecat (Technological Center of Catalonia).

Join Catalunya Hydrogen Week for enriching discussions, project presentations and demonstrations of hydrogen technologies.

Official Event Website: https://setmanahidrogen.cat/

Event Agenda: https://setmanahidrogen.cat/0dc9b-services/

Join the Event: https://setmanahidrogen.cat/registre/

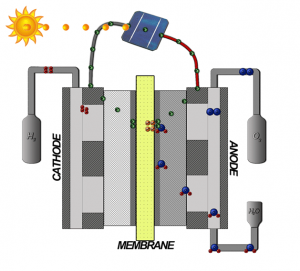

Design and assembly of new hydrogen generating reactors using PEM technology and possible applications in PEM fuel cells

This doctoral thesis will have as its main objective the “Design and assembly of hydrogen generating reactors and reverse process of electricity generation from H2 (fuel cells) based on PEM technology”.

The thesis is part of a broader idea of collaboration that also includes the study of hydrogen storage in composite material reservoirs and the use of hydrides. The entities participating in this thesis are SIEBC, a company in the field of industrial gases, Rovira i Virgili University and the Eurecat Technology Center.

The general objective of the project, in which we want to include this doctoral thesis, is to generate a business around a new technology to generate hydrogen in situ that is much cheaper and safer than current systems and with modularity depending on the necessary capacity and power. This technology will be complemented by the development of a safe storage system, as well as pipeline systems that will make it possible to transport hydrogen from distribution centers to supply points.

Green hydrogen has gained great relevance as a source of clean and renewable energy. Green hydrogen is produced from the electrolysis of water using renewable electricity, such as that generated by solar panels or wind turbines. Unlike conventional hydrogen, which is obtained from fossil fuels, green hydrogen does not emit carbon dioxide or other greenhouse gases during its production or use, making it a promising alternative to address climate change and reduce dependence on fossil fuels.

In addition, the study and optimization of pipelines for the transport and utilization of gases in decarbonization is also carried out from the wider point of view.

The prior knowledge of Eurecat and the URV (centered on Dr. Ricard Garcia Valls and his staff teams at the two institutions) is at a scale of TRL3-4, in mono cells, but currently scaling up to TRL5 internally This thesis aims to reach a TRL7 for a pre-commercial demonstrator.

In order to achieve this, the following stages are defined:

1- Bibliographic study of the state of the art for small electrolyzers (5Nm3/h) in order to decide the starting point (For example, Stack consumption: 4.7 kWh/Nm3 H2, AC power consumption (BoP + stack) : 5.5 kWh/Nm3 H2)

2- Replica of mono-cell manufacture of standardized size with materials currently on the market. Cell fabrication and testing.

3- Modifications of materials in the cell with own innovations. Performance essay.

4- Assembly of a stack of 3 cells equal to those tested in point 3.

5- Assembly of a stack of up to 0.1-1kW, its test and optimization. Recommendations for the manufacture of units up to 30kW.

6- Study of the effects of the quality of the supplied water and aging of the units.

Finally, it will be proposed to manufacture a pilot model on a pre-commercial scale that the company can present as a prototype as well as the application of some developed concepts, such as the sealing of the units, the production of MEAs and bipolar plates, for to the immediate construction of 0.1-1.0kW scale PEM cells as a test case for larger units.

Design of reactive systems for hydrogen storage

The main objective of this doctoral thesis will be the “Design of reactive systems for hydrogen storage”.

The thesis is part of a broader idea of collaboration that also includes the study of hydrogen storage in composite tanks and the use of hydrides. The entities participating in this thesis are SIEBC, a company in the field of industrial gases, the Rovira i Virgili University and the Eurecat Technology Center. Both the university and the technological center do so via e

In addition, the study and optimization of pipelines for the transport and use of gases in decarbonization is also carried out from the broadest point of view. The previous knowledge of Eurecat and URV (centered on Dr. Ricard Garcia Valls and his staff teams in both institutions) has reactors that allow the accommodation of several fixed beds in order to realize the final prototype.

To achieve this, the following stages are defined:

1- Bibliographic study of the state of the art of the use of reversible reactive systems using hydrogen gas.

2- Assembly of a fixed bed reactor with different combinations of catalysts.

3- Study of the kinetics and the conditions of temperature and pressure. Duty cycle test.

4- Modifications of the designed reactor to adapt it to the appropriate functions and cycles.

5- Assembly of a reactor on a larger scale in order to evaluate the scaling parameters.

6- Final design and definition of the working conditions of the storage system.

Ricard García Valls is the new director of the Chemical Engineering Department

The proposal is to strengthen the different lines of research and innovation, balance the staff, unify the department and improve internal and external relations.

Ricard Garcia Valls is the new director of the Department of Chemical Engineering of the URV with the favorable votes of 39 of the 45 votes cast by the Department Council in the elections held this October 2. He takes over from Joan Salvadó and will be accompanied by Fèlix Llovell as secretary of the Department.

D. in Chemical Sciences from the UAB in 1995, Garcia Valls did a postdoctoral stay at MIT from 1996 to 1998, at the Department of Chemical Engineering with Professor Alan Hatton. Since 1998 he has been a professor in the Department of Chemical Engineering at the URV and has been the sub-director and director of the ETSEQ.

He is a researcher in the field of chemical technology, especially in membrane separation and encapsulation technologies and operations, and in recent years has specialized in fuel cells and decarbonization. It has done so specifically in hydrogen and CO2 capture and transformation. From 2020 until today he has been director of the chemical technology unit of Eurecat, from where he has promoted together with his team that hydrogen is led internally and externally from Tarragona. He is also a member of different commissions in Catalonia and Spain for decarbonization and for the chemical industry.

He has supervised 16 doctoral theses, published over a hundred indexed scientific articles, has two patent registrations and has directed more than fifty public and private projects. His main line of research focuses on the application of chemical technology in medicine and more specifically for the treatment of cancer using encapsulation technologies. From the teaching point of view, he has taught subjects in the speciality of chemical engineering sciences and has specialized in the methodology of integrative advanced projects, working with open team projects and applying the international principles of CDIO (conceive, design, implement and operate), which he has established in the open laboratory in chemical engineering and the ChemEcar competition.

As for the management of the Department of Chemical Engineering, Ricard Garcia Valls proposes first to improve the internal cohesion of the department, to increase internal communication and to have an external image. He intends to manage the available resources in order to have the best possible working conditions, to reinforce all the work lines in research and innovation, as well as to balance the staff of both teaching and research support people, in a transversal way for all the research lines or groups. This improvement is also expected to have an impact on the balanced teaching activities for the teaching and research staff of the department.

It also aims to improve relations with other departments, centers and management bodies. Relationships with institutions outside the University, from the business, social and innovation world in order to take advantage of all the existing talent in the department and make it attractive, both to attract new talent, and to society in general, from the closest to the farthest geographically.

May 2023

Siebc Nordwest SL has reached an agreement with Eurecat research center to develop and improve technologies for transport, storage and production of green hydrogen.

Our reinforced polymer pipes and tanks will work at high pressures with H2.

Our PEM electrolysers will have an innovative membrane technology that will be produced by Siebc group in Spain.

Eurecat is the leading organization in Catalonia in the environnement of industrial research having several laboratories through the territory and collaborating with all the universities.

www.eurecat.org

February 2023

The SIEBC group has reached an agreement to enter the capital of the Chinese company manufacturer of reinforced thermoplastic pipes, BAOJI TIANLIAN HOUITONG COMPOSITE MATERIAL CO, LTD.

In addition to the purchase of shares in the BAOJI TIANLIAN company, the commitments acquired will allow rapid technical and commercial development of large diameters and technologies where the hydrogen molecule will practically not permeate, thus allowing applications with high H2S content. and green H2.

BAOJI TIANLIAN is an API Q1, API 15S, ISO 9001, ISO 14001 and ISO 45001 certified company. Thanks to the excellence of TIANLIAN engineers and the collaboration with the SIEBC group, the RTP pipe production plants in Dammam and Velikie Luki furthermore than the R&D center in Spain will benefit from the technical synergies generated.

January 2023

Siebc group and its Saudi partner have opened a commercial office in Dammam to serve the Middle East countries. Meanwhile the RTP factory works are moving forward according to plan.

December 2022

The authorities in the Kingdom of Saudi Arabia have provided the industrial investment License to build and run a new Reinforced Thermoplastic pipe factory. Soon Our group in partnership will be producing RTP pipes from 4″ to 8″ and operating pressures up to 3.000 psi.

November 2022

Siebc group has reach a technical agreement to support the Andorran Association for the study of Hydrogen and its applications.

www.a-h2.org

May 2022

Siebc group through its branch company in Peru has been awarded with a large project in the supply of pipe casing equipment that will help to increase the local oil production in new plots.

February 2022

Siebc group through its branch company in Peru has been awarded with a big project in the supply of drilling equipment that will help to increase the local oil production in new plots.

January 2022

The group Siebc has reached an agreement with a Saudi Arabian partner to open a new production plant for Reinforced Thermoplastic pipes in Al-Khobar. It is expected to be producing on the last quarter of 2022. The initial 30 million Euros Investment will be increased in the next years with the production of new piping and umbilical systems in onshore and offshore applications.

December 2021

Development and publish of a new Geofittings website – www.geofittings.eu

November 2021

New moulds for geofittings electrofusion finished and in production in Ecoplastol (Poland).

New items available in our production range.

May 2021

SIEBC has reached an agreement with ECOPLASTOL SP zoo from Malinowice, Poland for the promotion of the GEOFITTINGS electrofusion fittings worldwide. ECOPLASTOL is a family owned factory producing electrofusion fittings since 1991 being leaders in Poland, Russia and Ukraine. GEOFITTINGS are produced, tested and certified according ISO and European regulation for gas and water applications. SIEBC and ECOPLASTOL will also develop together products for green hydrogen applications.

March 2021

Siebc Nordwest SL participates, as a technological partner, in a project for the development of the first airport in the world operating with green hydrogen as an energy vector in all its mobility systems, airplanes, cars, buses, cargo and industrial equipment.

The Siebc group will be the technological manager of the implementation of the project, designing, producing and installing a 1MW electrolyser, the pipeline and storage systems, as well as a hydrogen refueling station. We have in this project with the collaboration of the Polytechnic University of Catalonia.

This totally innovative project has institutional support and the main world leaders of the airport and aviation sector.

February 2021

Siebc SL has started collaboration with the Chair of Chemistry in a Catalonian University, Spain, for developing together a unique and innovative hydrogen generator based on AEM technology which will reduce the power consumption, a fuel cell and a creative way to storage hydrogen in a non-gaseous state.

Actual Hydrogen generators supplied by the group Siebc work with alkaline generators. A strong and reliable technology.

January 2021

The move to the production premises in Russia has been finished.

The move to the production premises in Russia has been finished.

Inauguration was done but waiting the best time when the COVID will finish to make great inauguration party.

We expect that our clients and friends will be able to join us. Whishing that all of us will be soon together in good health.

Our pipe brand Fortiuspipe will be produced in the same premises.

December 2020

Siebc Group has opened a new company in Spain called SIEBC NORDWEST SL

This new company will be specialized in the production of Hydrogen generators, fuel cells and hydrogen refuelling stations.

Engineers are starting the R+D projects designed the first prototypes.

November 2020

Siebc Group through its production plant in Russia, Pipeline Systems Oiltech LLC, have reached a production joint venture agreement with Nordwest LLC.

Siebc Group through its production plant in Russia, Pipeline Systems Oiltech LLC, have reached a production joint venture agreement with Nordwest LLC.

The reinforced thermoplastic pipes will be produced in the same new premises and the future technical development of polyester and carbon fibre reinforcement pipes will be designed and tested in Russia and Spain.

The range of textile pipes will include sliplining and close-fit sliplining rehabilitation pipes.

Engineers from Russia and Spain will work together to develop high-pressure piping and storage systems for gaseous applications specially oriented to green energy applications.

The pipe operating pressures are 20-40-100 and 200 bars

The pipe operating temperatures are 65ºC-85ºC and 120ºC

Pipe diameters 2”-3”-4”-6” and 8”

Carbon fibre storage tanks will work at 350 and 700 bars